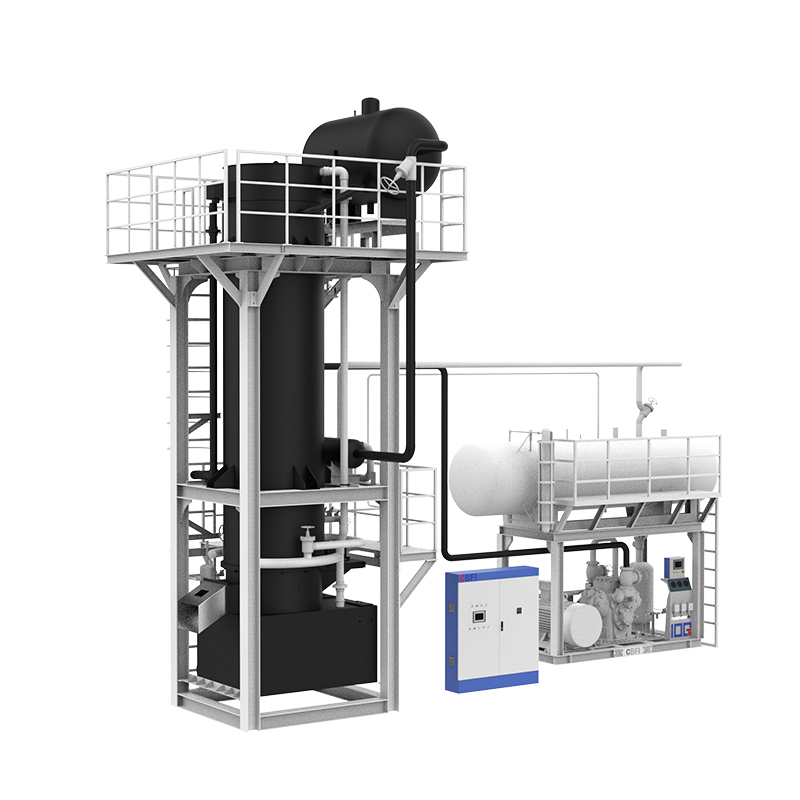

The CBFI ammonia tube ice machine uses ammonia (NH₃) as a refrigerant, featuring Mycom compressor technology for high efficiency and energy savings. Ideal for expanding ice production, it offers flexible design, easy installation, and maintenance, and produces high-quality ice while meeting environmental standards. CBFI provides reliable global support and services.

Brand:

CBFIWhat is ammonia tube ice machine?

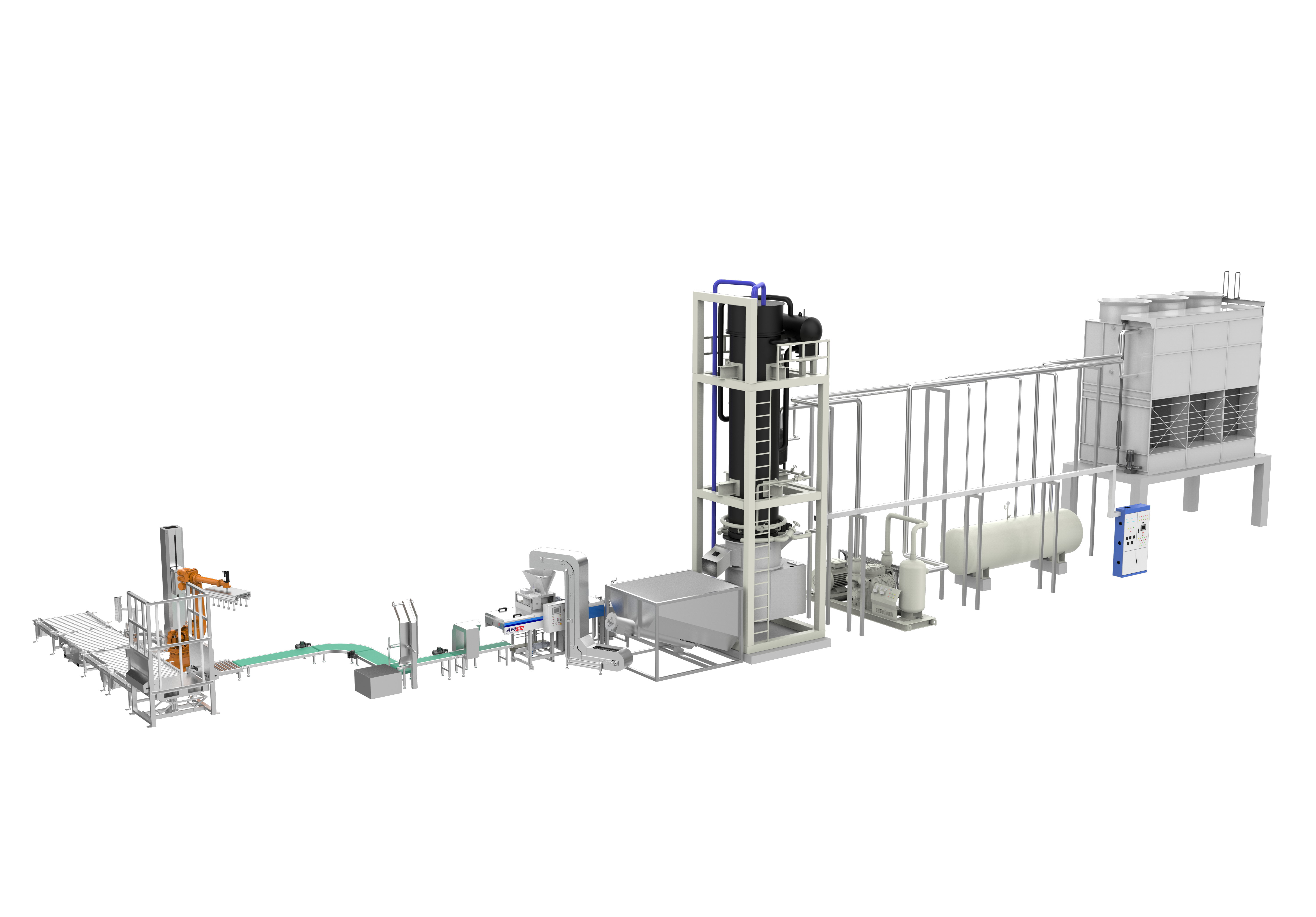

Ammonia tube ice machine is a device that uses ammonia (NH₃) as a refrigerant to produce ice through tubular evaporators. Ammonia, as an efficient refrigerant, has excellent thermal conductivity, making ammonia tube ice machines highly popular for large-scale and industrial applications. CBFI's ammonia tube ice machines utilize Mycom compressor technology, characterized by high efficiency and energy savings. Combined with automatic packaging and stacking devices, CBFI's ammonia tube ice machines can provide strong and stable production support for your ice-making business. They are especially suitable for businesses looking to increase tube ice production and expand their ice production line.

Advantages of CBFI ammonia tube ice machine

Mycom Compressor Technology - Air-Cooled M-Model

MYCOM compressors have been renowned worldwide for 70 years, excelling in energy efficiency, stability, and reliability.

Efficient, Stable, and Reliable:The unique long-stroke design effectively improves the compression efficiency ratio, reduces vibration and noise, providing the compressor with outstanding cooling performance and stability, ensuring long-term efficient operation of the system.

Sustainability:Mycom is known for its commitment to environmental sustainability. The long-stroke M-model compressor design aims to minimize emissions and comply with environmental regulations, making it a responsible choice for businesses focused on sustainability.

Global Service Network:Mycom has established an extensive service network worldwide, capable of providing timely and professional after-sales support to global customers. Local service centers in major markets offer fast-response localized services to meet customers' urgent needs.

Design Advantages:

Flexibility:The split design makes the installation of the tube ice machine more flexible and adaptable, allowing for configuration according to site-specific requirements.

Space Utilization:Optimized layout based on the characteristics of the tube ice plant, with an upper and lower layer design to enhance space utilization and effectively reduce piping, saving installation time.

Ease of Maintenance:The modular design ensures that each module is independent and easily accessible, facilitating regular inspections and maintenance to ensure long-term stable operation of the equipment.

Advantages of Ammonia Refrigeration System

High Coefficient of Performance (COP):Ammonia (NH3) as a refrigerant has a high coefficient of performance, meaning that with the same power consumption, an ammonia refrigeration system can provide greater cooling capacity, thereby reducing operating costs.

Eco-Friendly and Energy-Efficient:Ammonia is an environmentally friendly and efficient refrigerant that meets environmental standards, helping to enhance a company's green image.

High-Quality Ice Production:The system can quickly cool and form ice, producing ice with high density and good transparency, meeting the demands for high-quality and high-capacity ice production.

Stable System Operation:The ammonia refrigeration system performs stably under high loads and complex conditions, maintaining efficient operation for extended periods, and reducing failure rates and downtime.

How is an Ammonia Tube Ice Machine Produced? —— Ammonia Tube Ice Machine Production ProcessUnique Mechanical Strength Expansion Technology:Our company uses a unique mechanical strength expansion technology to ensure the seal between the upper and lower layers of the separator, allowing for smoother ice release.

Rapid Ice Release Technology:CBFI holds several invention patents and uses a uniquely designed refrigeration system to achieve rapid ice release, significantly increasing ice production.

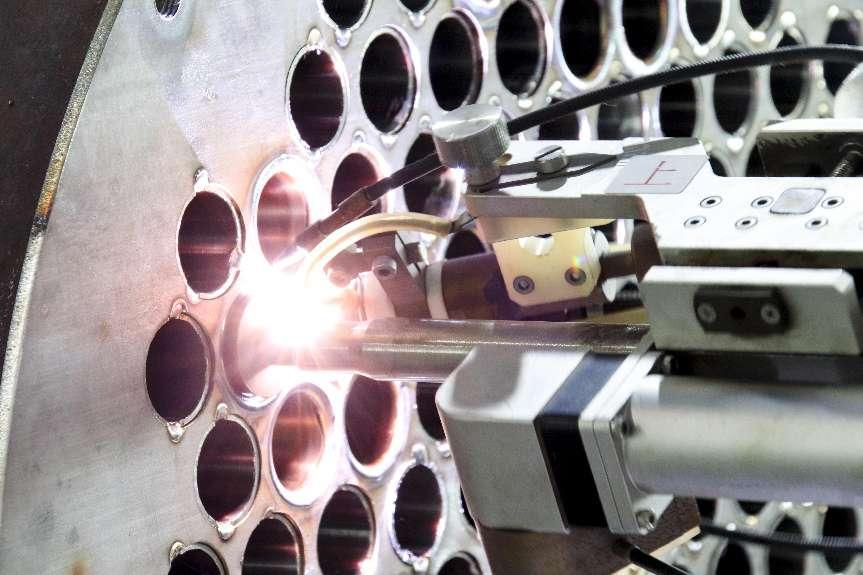

Evaporation Barrel Laser Flaw Detection:Multiple quality inspection processes and specialized detection equipment ensure the production quality of the equipment.

Services and Support

24-Hour Global Support:CBFI provides 24-hour response services to customers worldwide, ensuring issues are resolved promptly to minimize downtime and maintain operational efficiency.

Extensive Experience and Expertise:With over 16 years of experience in the refrigeration and ice-making industry, CBFI has accumulated extensive knowledge and professional skills. This enables them to address various customer needs and provide customized solutions.

Comprehensive Training Programs:CBFI offers detailed training to customers, ensuring they are equipped to operate and maintain the equipment. This training helps maximize the equipment's lifespan and improve efficiency.

Global Reach and Localized Service:CBFI's customers span over 150 countries, with a strong global network capable of providing localized support and services.

With these technological advantages, we believe our split ammonia refrigeration system tube ice machine offers superior performance and competitiveness, providing customers with reliable and efficient cooling solutions. If you have any questions or needs regarding our products, please feel free to contact us, and we will be delighted to assist you!