With summer heat wreaking havoc, nothing beats a refreshing ice-cold drink to cool off. If there's something better, it's having another one!

This season, seizing the market opportunity for edible ice can not only satisfy public demand but also help you ride the wave of the summer economy and reap substantial rewards.

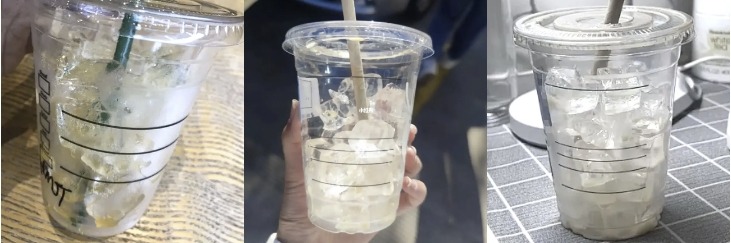

Have you ever noticed how your homemade ice cubes melt much faster than those from cold drink shops? Homemade ice melts within minutes, while ice in milk tea or coffee shops seems to last much longer, barely melting during an entire movie.

Slow-melting ice maintains the taste and flavor of the drink.

Why does the ice sold in stores melt more slowly? There are several key factors:

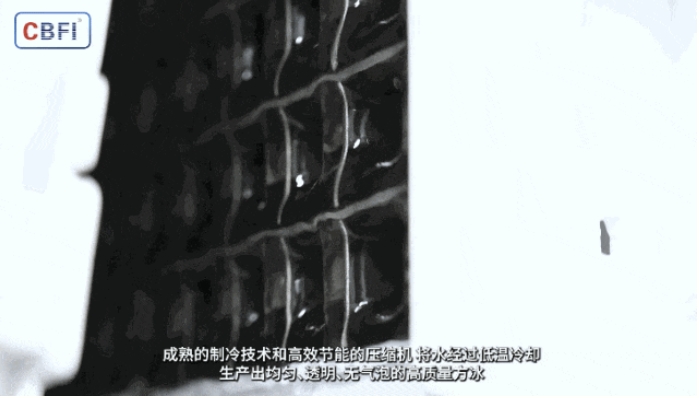

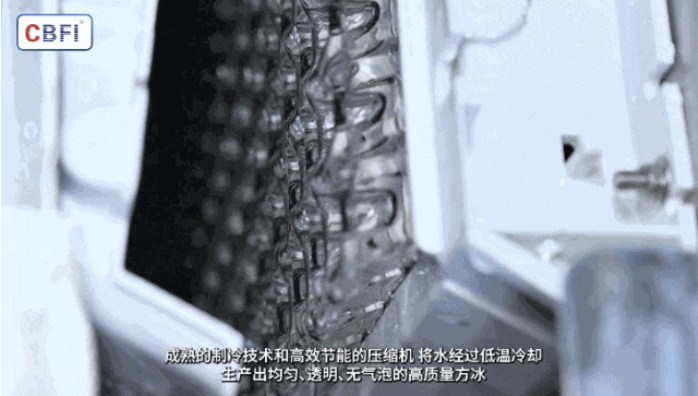

Industrial edible ice is typically made from water that has been filtered and purified through multiple stages, removing air, impurities, and minerals. Ice made from purified water has a more uniform and compact internal structure, which makes it melt more slowly.

Diamond-like pure ice cubes.

Homemade ice cubes, however, are often made from less pure water, which causes impurities to form cloudy spots within the ice. This type of ice is known as "cloudy ice."

Ice cubes formed from impure water (Image source: online).

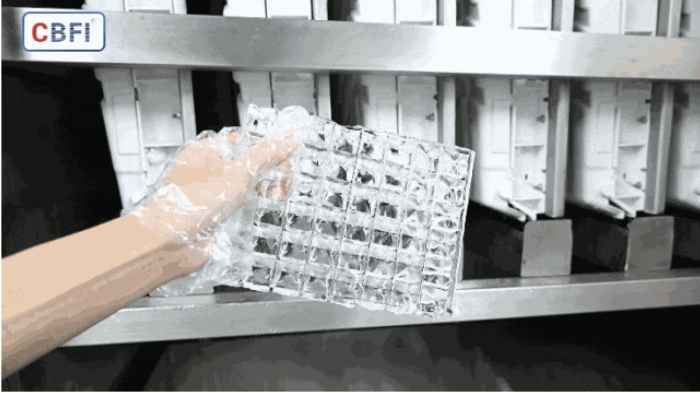

Industrial ice makers use high-efficiency dynamic freezing methods, which allow for the rapid and continuous production of ice cubes. Unlike static freezing methods (such as traditional freezer ice), these machines employ patented high-efficiency automatic ice removal technology, which results in low energy consumption and rapid ice release.

Industrial ice machines use high-efficiency dynamic freezing methods.

Rapid freezing prevents the growth of large ice crystals, resulting in fine, dense ice crystals that help the ice cubes stay stable and melt more slowly.

Temperature control during both ice production and storage is extremely strict. Rapid freezing and optimal storage temperatures reduce internal stress in the ice cubes, enhancing their hardness and slow-melting properties.

CBFI has over 20 years of experience in refrigeration technology, with patented high-efficiency refrigeration systems and block ice machine water flow design that ensure uniform water distribution and efficient cooling. This ensures the ice forms at the optimal temperature.

CBFI holds 69 authorized patents, as shown in the image for related block ice machine patents.

The industrial production environment undergoes sterilization treatments, and separate production zones for operations and ice-making areas prevent bacterial and microbial contamination. This not only ensures the hygienic safety of the edible ice but also indirectly enhances the ice's slow-melting properties since microorganisms accelerate the decomposition of ice.

Image of a food-grade ice production facility.

Optimized industrial ice shapes, such as tube ice, reduce the surface area exposed to air, which reduces the rate of heat exchange and thus improves slow-melting properties.

In conclusion, industrial edible ice melts more slowly because high-standard technologies and management are applied throughout every stage, from water purification to ice-making processes and storage, ensuring the quality and performance of the ice cubes.

CBFI offers one-stop edible ice plant solutions that include water treatment workshops, main control rooms, ice-making workshops, ice drying areas, ice pellet packing rooms, external packaging areas, and ice storage cold rooms.

Feel free to leave a comment or contact us for your plant requirements (name + desired equipment + production capacity + contact info) to quickly receive an ice plant proposal and quotation.

CBFI always places customer satisfaction at the core of its services.

With over 20 years of experience in designing and engineering large-scale edible ice plants worldwide, CBFI has served clients in over 170 countries and regions.

As one of the drafters of the "Food Ice Production and Hygiene Standards" issued by the China Food Industry Association, CBFI continues to actively promote the "Ice is Food" food safety concept.