Daily Production: 3 tons 24 hrs

3 ton tube ice machine is a good choice for commercial ice business.

Brand:

CBFIItem NO.:

TV30Shipping Port:

Guangzhou PortWarranty:

1 yearCBFI TV30 3 ton per 24h tube ice machine

Features of CBFI Tube Ice Machine

Daily Production: 3 tons 24 hrs

3 ton tube ice machine is a good choice for commercial ice business. The ice plant design provided is able to make the machine operation during night, to make more profit for you.

1. 3D design, convenient for container transportation, simple installation and maintenance.

2. The evaporator adopts stainless steel polyurethane foam insulation, and the pipeline adopts insulation treatment, which is more energy-saving and has a beautiful appearance.

3. The parts in contact with ice are made of food-grade high-quality 304 stainless steel to ensure ice safety and sanitation.

4. PLC intelligent control system, fully automated production, without manual operation.

5. Using automatic laser welding machine to weld, the welding spot is beautiful, no leakage is guaranteed, and the equipment failure rate is low.

6. The whole machine has passed CE certification, which has high security.

7. The special water system design ensures better ice quality, uniform thickness, transparency and purity.

8. Unique ice removal method, fast ice removal speed, less system impact, higher efficiency and safer.

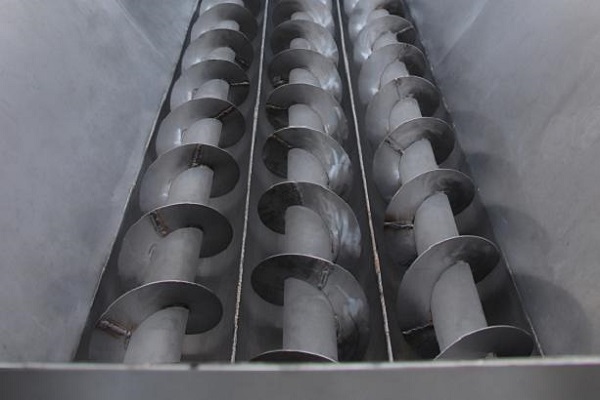

9. It can be equipped with stainless steel spiral conveying ice storage hopper, manual or automatic packing system.

Machine Details

|

|

|

|

|

|

Parameters

| TV30 Tube Ice Machine Parameters | ||||

| Name | Unit | Parameter | ||

| Tube Diameter | mm | Φ22 | Φ28 | Φ35 |

| Bitzer Compressor Parameter | Model | 4NES-14 | ||

| Cooling Capacity(kW) | 29.3 | |||

| Power(kW) | 10 | |||

| Condenser | Heat Exchange(kW) | 53 | ||

| Condensing Temperature | Degree Celsius(℃) | 40 | ||

| Evaporating Temperature | Degree Celsius(℃) | -10 | ||

| Ambient Temperature | Degree Celsius(℃) | 25 | ||

| Water Temperature | Degree Celsius(℃) | 21 | ||

| Refrigerant | R507 | |||

| Voltage | V/P/HZ | 380/3/50 | ||

| Motor Power | Ice Cutting Motor(kW) | 0.75 | ||

| Recircling Pump(kW) | 0.75 | |||

| Cooling Tower | Power(kW) | 0.25 | ||

| Cooling Pump | Power | 1.1 | ||

| Water Cooling Machine Dimension | L*W*H(mm) |

1500*1350*2077 |

||

Quality Control

|

|

|

|

|

|